Design

-What you need to store determines the size of your shed.

Make sure you design the size of the shed to hold everything you want to keep dry. I always recommend going bigger than you think. Consider adding a lean-to on the side or back of your shed to store things like firewood.

-Materials you are going to use.

Determine early what you want to build your shed out of. It will help you down the road when you want to get quotes. For instance, what type of siding or roofing?

-Are you running electricity?

-Do you want windows or skylights?

Personally, I am not a big advocate for windows since they are easy to break into and limit your wall storage. However, that being said windows and skylights can be nice for lighting if you don’t plan on running electricity.

-How big does the door need to be?

If you need to roll a lawnmower or quad through the opening, make sure you account for that in your design.

-Jurisdictional requirements

Check with your city officials to see if there are requirements for property line setbacks, size and height restrictions or even fire codes. In some cases you may have to pull permits. Some jurisdictions may require permits based on whether or not it is a “permanent” structure, plan your design accordingly.

Choosing your site

-Access to your yard

Choose a spot in your yard that has easy access and is secure from would be criminals. Consider how wet the ground gets since you won’t want to be sloshing through your yard to gain access to your stuff.

-Electricity

If you want electrical lights and receptacles in your shed you will more than likely have to pull permits. The easiest way to wire it would be underground through specialized conduit. Think about other utilities that may be in your way or other obstacles like concrete patios or trees. Always have a locating crew come out and show you where things are under the ground!

Foundation

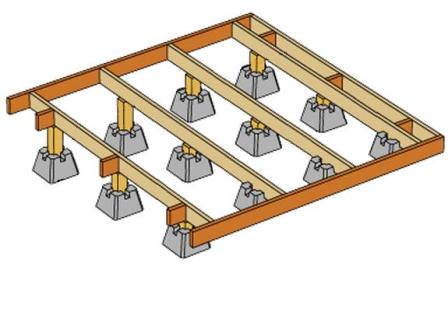

-Slab vs. Framing

Pouring a slab definitely makes for a more solid foundation. Although, depending on how big it is you may have to pull permits and supply an engineered plan for your building. If you aren’t building a second garage than the easiest thing to do is frame a joisted floor on footings and deck it with plywood. It is also easier to build by yourself and more cost effective.

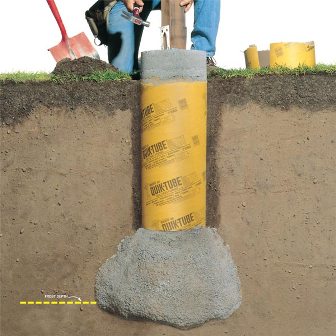

-Pier Pads Vs. Poured Footings

Pier pads are an inexpensive and easy way to build off the ground. If you are worried about your building from sinking into the ground you may want to consider pouring footings. You can dig down below your frost line and use cardboard form tubes to make a clean and stable footing.

-Gravel

A gravel floor can be used if you are building a pole style building.

-Pressure Treated Lumber vs. Standard Lumber

The best material for building the floor of your shed is pressure treated lumber. You can certainly use regular non PT but it won’t last very long being that close to the ground.

-How high off the ground?

Think about how high off the ground you want your shed. If you live in an area that can flood you may want to bui

Framing

-Green vs. Dry

In the Pacific Northwest we have the choice of buying green lumber (wet from the mill) or dry lumber. Dry lumber offers the advantage of being lighter since water weighs about 8lbs. a gallon. Typically dry means less than 19% so you will also limit your chance of getting mold growth…. Although, you may not care since it’s a shed.

-2×4 or 2×6 walls

Typically speaking 2×4 construction is more than adequate for the shed walls.

-Header Sizes

The headers for your door or window openings depend on the amount of roof load. A gable end will have very little load while a hip roof will have extra load. Parr Lumber has the ability to tell you what size header you need for a specific opening.

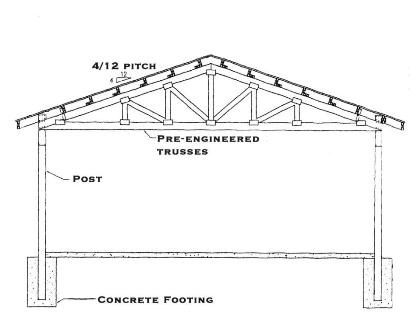

-Pole Barn Style

A pole building is a simple way of construction that requires burying posts in the ground 4′-6′ on center and spanning beams on top of them. You would usually see this type of building on a farm and in a much larger scale. You could use this method to make a small shed but it would be open to below.

-Decking

CDX plywood is the most economical choice for decking your shed. For those of you that don’t know, CDX means that the plywood has a C face and a D face (A being the best). The X means that is has exterior grade glue. As long as this plywood doesn’t see any long term moisture it should work just fine.

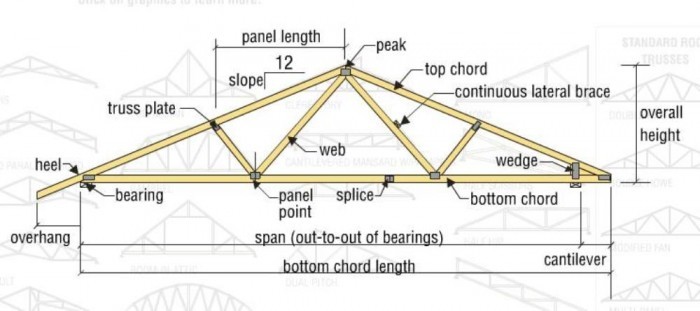

-Manufactured Trusses vs. Handcut

There is something satisfying about taking raw lumber and hand cutting a roof. With a little time you can easily frame a roof by yourself. However, if you don’t feel confident with it you can order manufactured trusses from your local Parr Lumber. Depending on the size of your shed you should expect to spend a few hundred dollars.

-Gable Roof, Gambrel Roof, Hip Roof, Shed Roof, Eco Roof

A shed roof is the easiest way to frame a roof. You basically frame one wall taller than the other and run your roof rafters at an angle to create slope. This is also a great starting point for building an eco roof. A gable roof is probably the most common style and is somewhat easy to frame for a DIY’er. Gambrel roofs are the classic “barn” style with a double pitch.

-Roofing options – Composition, Metal, Polycarbonate, Eco

Composition architectural shingles over felt paper is the most common roofing out there. Metal panels are another option and can be ordered to the inch so cutting isn’t necessary. You can work with your Parr Lumber salesperson to make sure you get all of the right trim and flashing. An Eco Roof is probably the most interesting of all. At least here in the Pacific Northwest we battle with moss growing on our roofs all year round. So why not let it grow? You start with a flat roof with a waterproof membrane similar to what you would use for a pond liner. Drains and parapets are also required but in the end with a little bit of time and money you can have your own rooftop garden! Find out more at www.greenroofs.org.

-Prehung Door vs. Homemade Door

I prefer to build my own door out of 2×4’s and plywood. However, you can certainly buy a prehung door and install it for a couple hundred dollars.

-Windows / Skylights

Windows are a double edged sword. They add light to the inside of your shed at the same time making it vulnerable to burglars. Skylights are a good idea if you have it in your budget. They will run a couple hundred dollars per opening while a small window is typically less than a hundred.

-Plywood vs. OSB

OSB gets a bad rap from the old timers. The reality is that OSB has evolved over the years to become a very reliable building material. The old days of OSB swelling to 3 times its thickness and growing mushrooms are long gone. It actually has a higher shear value than CDX plywood from an engineering standpoint. That being said I still recommend using CDX 5-ply for the roof because it doesn’t flex between the rafters like OSB.

-Siding choices – T1-11, Hardie, LP, Cedar

The most economical and easy siding is the good ole T1-11. It comes in grooved patterns 4″ and 8″ on center or even without grooves. You can build your walls “single wall” which means that the T1-11 acts as the siding and the sheathing. Fiber cement and LP siding are durable options as well. LP was run through the mud a few years back due to some product failure. However, they have done a great job re-engineering their siding and now offer a 50 year warranty.